CHONGQING ARISE TECHNOLOGY CO., LTD.

Booth Number: Hall 5.2 - 5.2B37

Add LAB Wechat for consultation

Share this page

Exhibitor E-invitation

Invitation / Product Poster

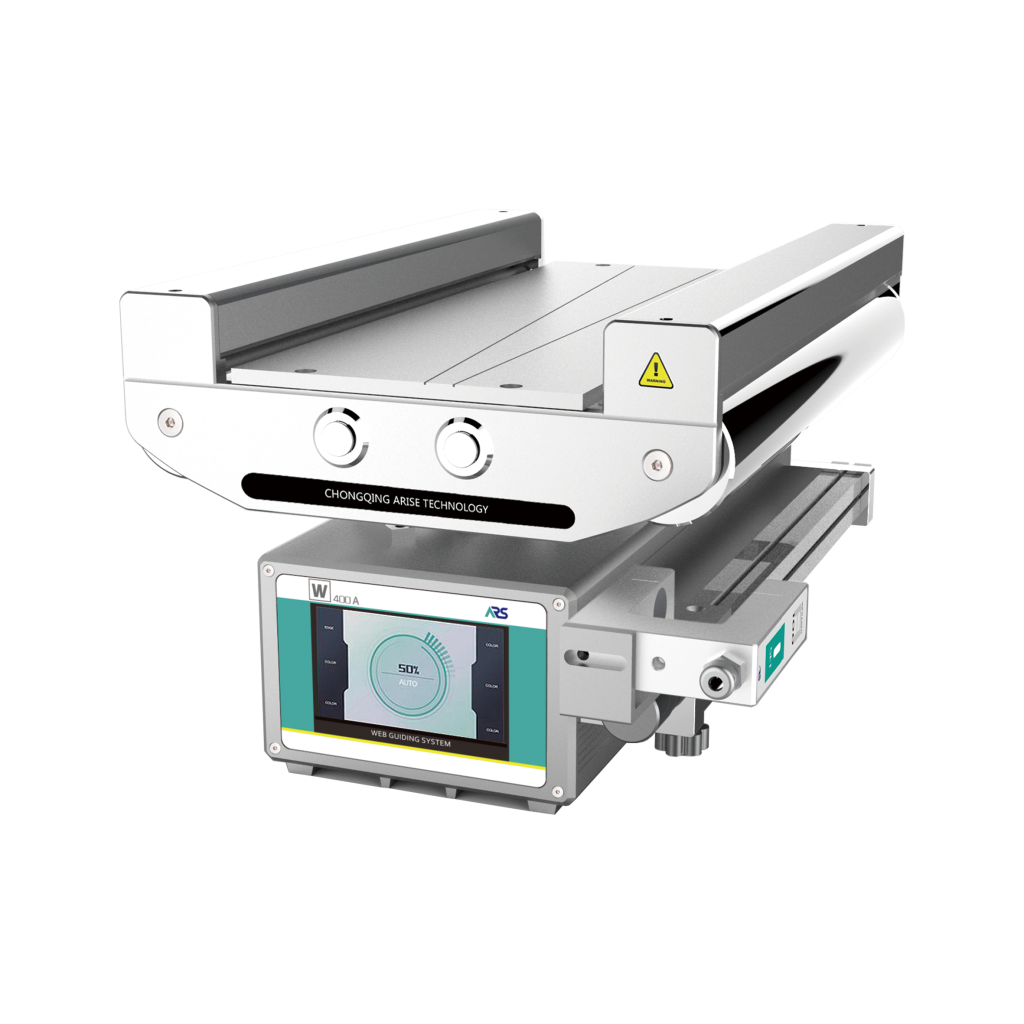

WEB GUIDE ALL-IN-ONE MACHINE WITH CUTTING TABLE

The W400 cutting table is equipped with a high-performance full touch screen operation and a servo error correction system, allowing for seamless material change on the convenient automatic hand press platform. It is specifically designed for precise tracking of material edges, lines, contrasts, and cutting operations. This machine is suitable for automated control in various industries such as label printing, flexo printing, and bag making. By utilizing ultrasonic, infrared, and CCD sensor detection signals to calculate material offsets accurately, it ensures efficient correction through drive servo motors and coding feedback.

TENSION CONTROL SYSTEM

T500 is a full-automatic tension controller. It adopts 16 - bit high-precision AD sampling for 1us. The sensor has high signal precision and high speed. It can drive magnetic powder brake. The sensor can be connected with single / double pressure sensors or can work automatically without internal calculation of sensors.

STATIONARY INSPECTION SYSTEM

When the printing press is running at high speed, the human eye cannot observe the quality of the printed image. A monitoring system must be used to observe the still image. The image monitoring system uses new technology and new methods to turn high-speed moving images into "still" images that are easily accepted by the human eye, and can be partially enlarged to detect small printing defects in time, and take corresponding measures to improve print quality.

思源黑体预加载(勿删): CHONGQING ARISE TECHNOLOGY CO., LTD.